Ventilation unit

This page is part of my Home Automation project.

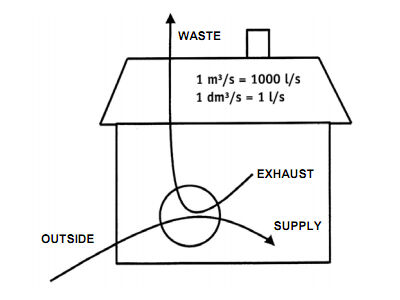

I have a ventilation unit with regenerative heat recovery (rotary heat exchanger) from Enervent. The model Pingvin EDE has digital remote control panel with modbus interface.

Enervent Pingvin ventilation unit and EDA control unit.

Enervent has published modbus register specifications of their ventilation units. Unfortunately in finnish only:

http://enervent.fi/data/fi/manuals/EDA_Modbus_rekisterilista_2011-02-16.pdf Local backup copy (pdf 293 kB)

Enervent uses modular 4p4c connector (phone cable), often informally called as RJ9, RJ10, or RJ22, for the modbus interface.

| Pin | Color | Signal |

|---|---|---|

| 1 | Black | +5VDC |

| 2 | Red | Data+ |

| 3 | Green | Data- |

| 4 | Yellow | GND |

With modbus (RS-485) interface adapter and library support, it is possible to communicate with the ventilation unit. See my Linux modbus support page.

Beware: The ventilation unit is acting as a master in the modbus network. Thus,all additional devices should be acting as a slave, in order to avoid collision.

EDA control unit has dual 4p4c connectors for chaining up to four control panels into single ventilation unit. That makes is very easy to attach computer into the loop, without need for hardware modifications or special branching cable.

In the bus, the ventilation unit acts as the master, and one or more user panels are slaves, having unique slave address from 1 to 4. The master polls the bus periodically, in order to seek for slaves. Values of read-only holding registers 1-50 are periodically distributed to all slaves, by sending messages with function code 16 to modbus broadcast address 0.